China’s Kitchen Utensils Manufacturer with over 20 Years Experience,

MAKE YOUR PURCHASING MORE EFFICIENT AND SAFE, especially in

silicone, plastic and stainless steel material.

There’s always be one set for your market, or customized your unique one to stand out in the crowd

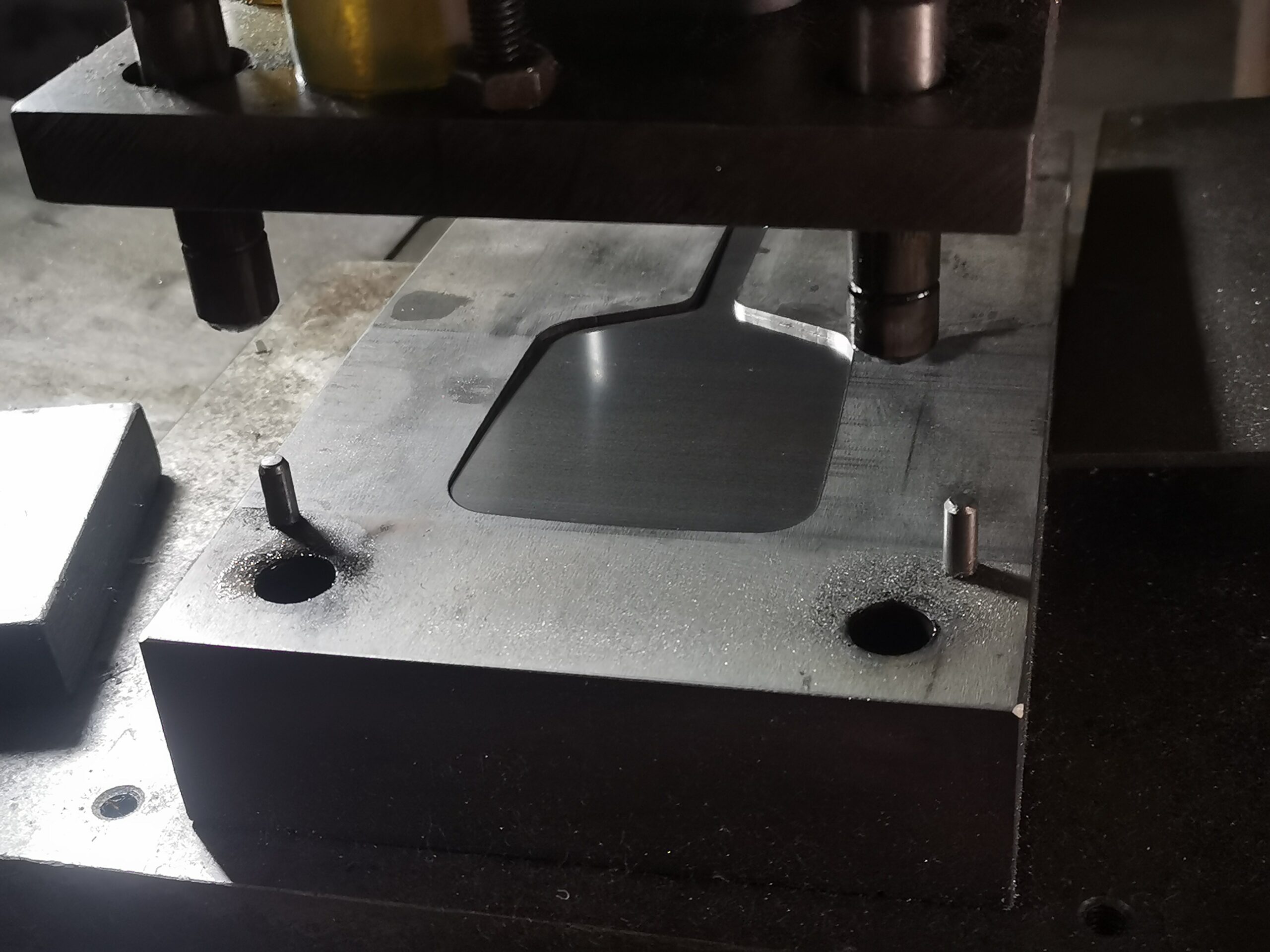

When it comes to custom, it will need to bulid a mould for mass production. According to the design draft, the volumn of mould cube will be set. Then use CNC machinery do the precise cutting while oil spraying to cool down the temperature. Next use the painting to find out whether inner part match or not. Using this way, it can help to mould the get more precise and patterned product.

Provide food-grade and platinum-grade silicone as request. The raw material all purchase from well-known supplier, Elkem、Radici、Dupont...

The silicone kitchenware will go through two-time vulcanization process. First time shaping by the Hydraulic Vulcanizing Machines. Second time baking in Secondary Cure Ovens.

For new material or new mould, there’s Initial Goods Inspection. First 5 items of mass production need to be tested, the production can be continue only after passing the test by CIQ.

It’s both 3,000pcs for existing item and customized item. If there is stock in the warehouse, then the MOQ can be 500pcs. So just contact us today to check the stock!

Of course!

Fusion is a new brand of our factory. In the past 20 years, we were doing great in OEM&ODM service with great brand. Now we are ready for more opportunity to stand out together with you in the market .

Our factory cover an are of 120,000㎡, include 6 workshops.

Welcome to visit! Our factory is located in the city scientific research base, niuetong, chengxi town, yangjiang, guangdong, china.

We will contact you within 1 working day, please pay attention to the email with the suffix “@linkfortune.cn”.